Treatment of PFAS – Contaminated Water

Diverse Standard & Custom Systems

With applications in groundwater, drinking water, surface water, wastewater, construction dewatering and IDW, ECT2 offers a range of treatment systems, including:

- Mobile treatment systems for short term water treatment activities.

- Modular systems for turn key.

- Fast installation.

- Quick start up projects.

- Custom designed systems to meet client-specific needs.

- Supplement, upgrade or replacement of existing carbon based treatment system.

- Supplemental treatment for existing facilities where PFAS is not currently being treated.

- Bespoke treatment systems to meet site-specific requirements.

The Ubiquitous

PFAS Family

PFAS are a very large group of synthetic chemicals that includes PFOA, PFOS, GenX chemicals, and potentially more than 4,000 other compounds that have been manufactured and used in a variety of industries worldwide since the 1940s. PFAS are found in a wide array of consumer products and industrial processes, including firefighting foams, chemical processing, building/construction, aerospace, electronics, semiconductor and automotive industries, stain- and water-resistant coatings, food packaging, and waxes and cleaners. Due to their strong carbon-fluorine bonds, many PFAS can be very persistent in the environment with degradation periods of years, decades, or longer. Most people in the United States have been exposed to these molecules, and there is evidence that continued exposure to certain PFAS above specific levels may lead to adverse health effects, such as developmental effects, cancer, liver effects, immune effects, and thyroid effects. As a result, the characterization, regulation and remediation of PFAS has become a primary focus of regulatory bodies around the world.

13x More Effective

Water Treatment

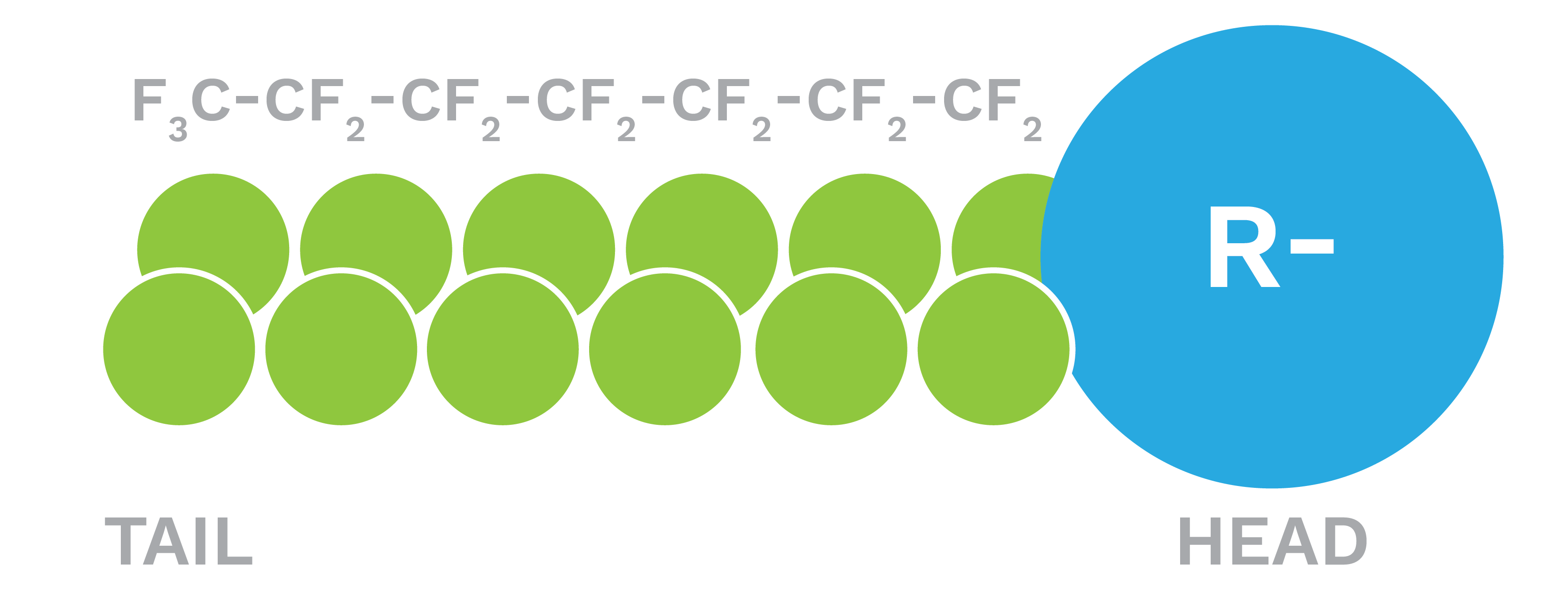

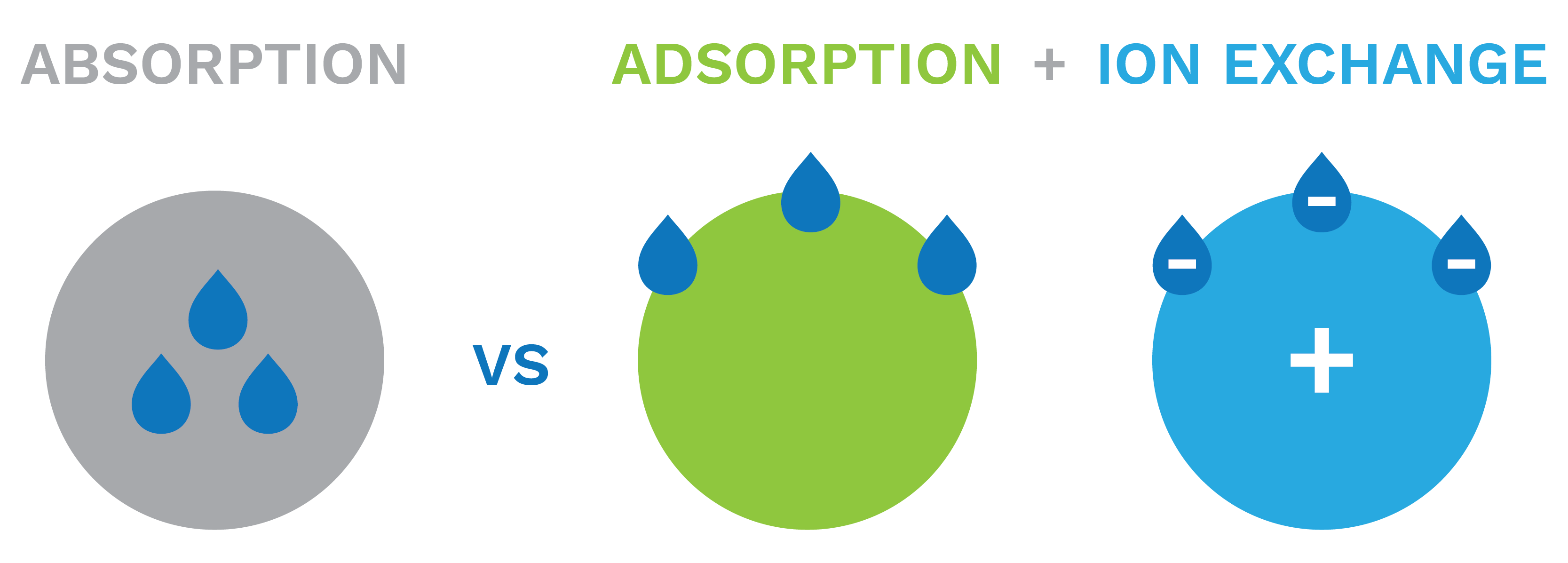

ECT2’s SORBIX™ PURE single use ion exchange resins provide advantages over other approaches, such as GAC and reverse osmosis filtration, in the removal of PFAS from water. These synthetic resins, composed of a neutral, hydrophobic backbone, divinylbenzene cross links, and positively charged exchange sites, are essentially adsorbents with ion exchange functionality. The hydrophobic carbon-fluorine tail of a typical PFAS molecule adsorbs to the resin’s hydrophobic backbone and cross links, and the negatively charged head of the PFAS molecule is attracted to the resin’s positively charged ion exchange site. This combination of adsorption and ion exchange produces a PFAS removal capacity that is 13x more effective in comparison to other technologies. SORBIX PURE is the most efficient technology on the market for removing PFAS compounds, including short chain molecules.

Up to 99% Less

Waste Generation

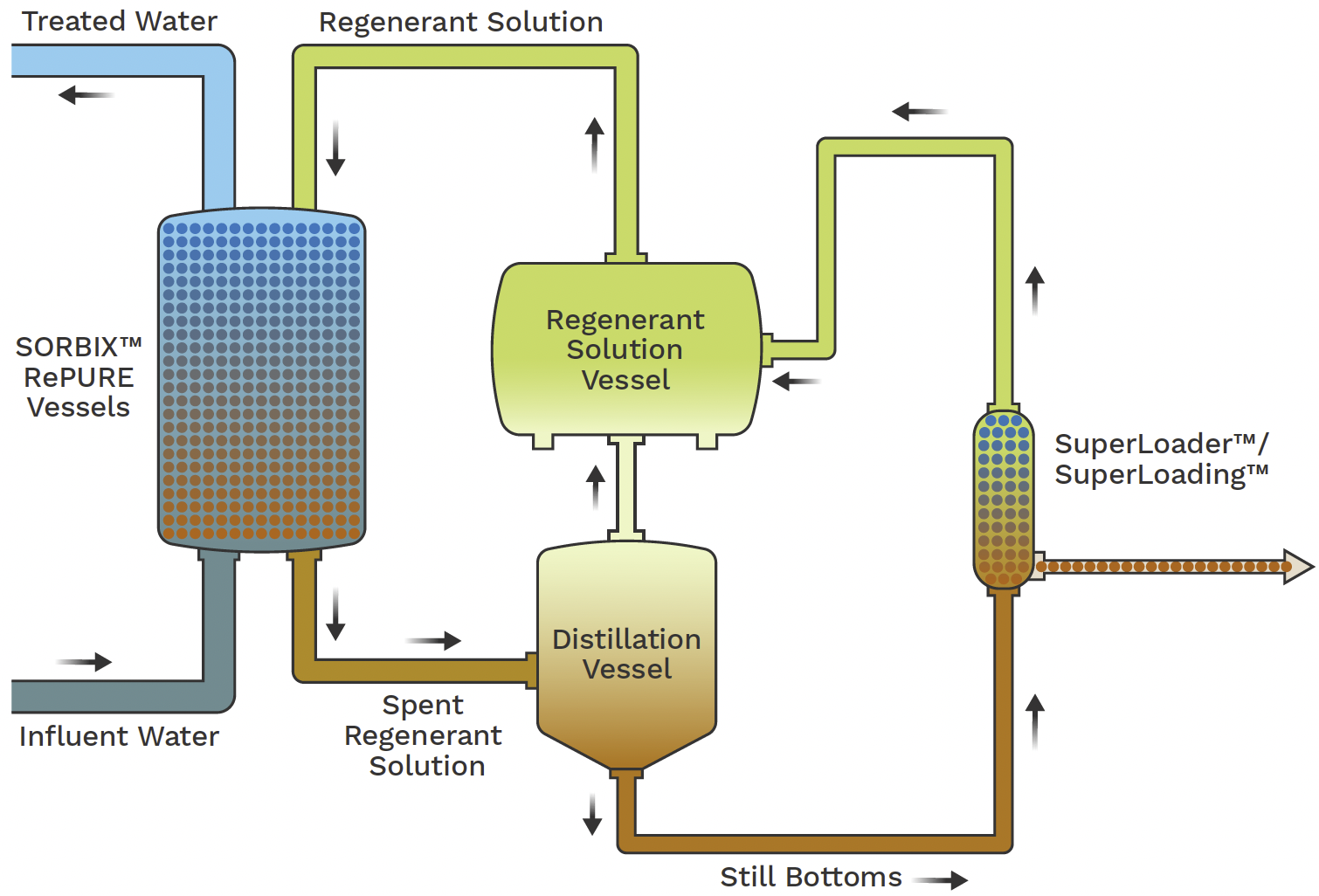

SORBIX™ RePURE is a patented technology, enabled by a proprietary specialty regenerant solution, that allows PFAS-saturated resin to be regenerated onsite and reused. Following regeneration of SORBIX RePURE, the PFAS-laden regenerant solution is processed through ECT2’s distillation and SuperLoading™ process, reducing waste generation by orders of magnitude. SORBIX RePURE has approximately 10 times the capacity of GAC and is best suited to applications where resin replacement would lead to high operating expenses, such as long-term installations, source-area remediation wells, high-concentration spillage or discharge, complex waters, or where management of short chain or precursor PFAS is important.

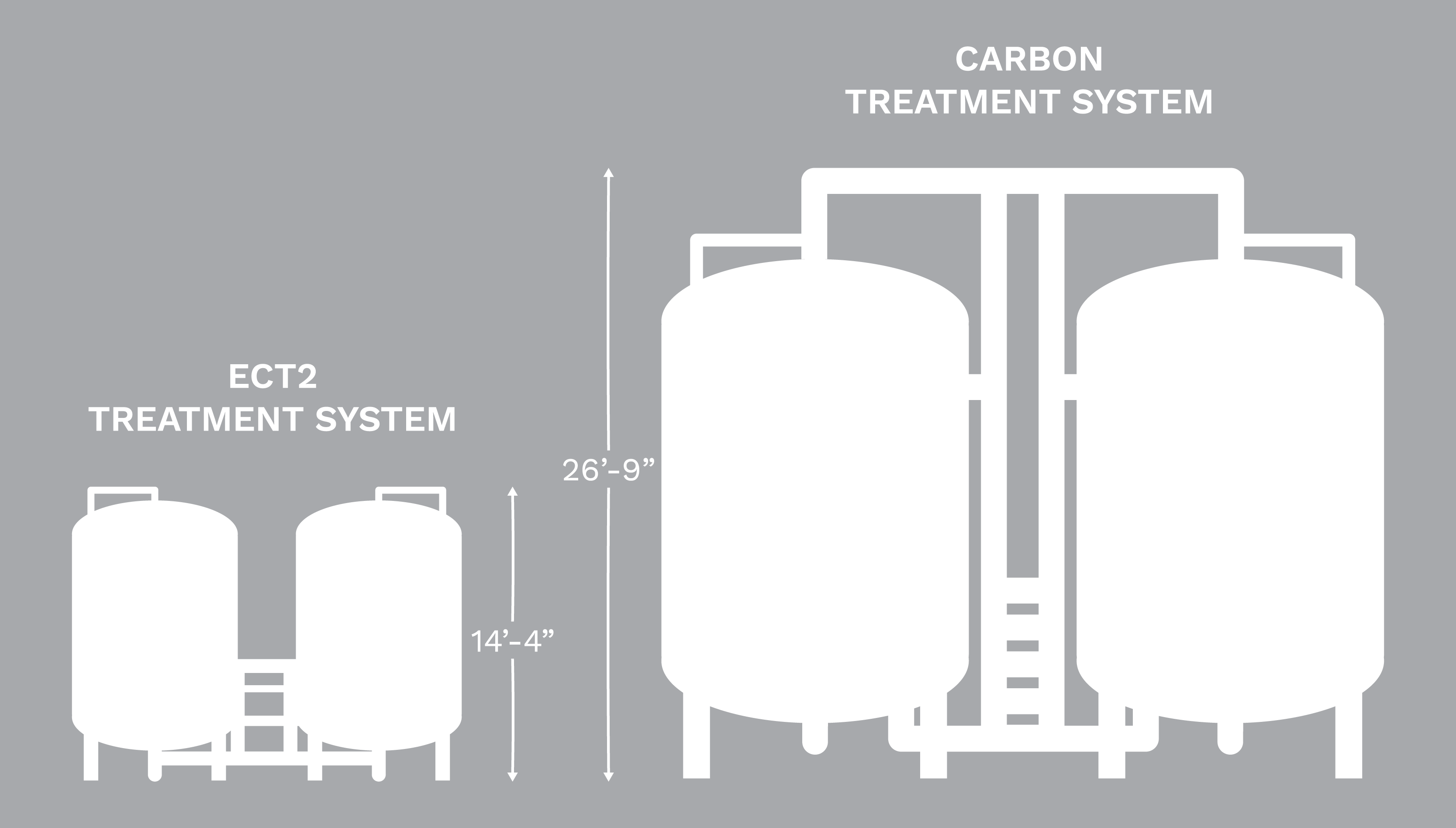

67% Reduction in

Treatment System Size

The SORBIX resin’s superior PFAS binding capacity in combination with the rapid kinetics of the binding reaction lead to longer run times between media changeouts and correspond to treatment system sizes that are significantly less than those of carbon, foam fractionation, and ozone fractionation treatment systems.

50% Reduction of

Life Cycle Costs

Twenty-Year Present Worth Analysis (USD)

1200 GPM Drinking Water Treatment Plant

Reduced system size requirements, longer run times between media changeouts, lower energy use, and reduced waste generation all contribute to lower capital outlays and annual operating expenses for our treatment systems, with twenty-year present worth analysis in third-party feasibility studies revealing that SORBIX treatment systems can reduce life cycle costs by 50% over competing technologies.

Treatment Option |

Capital Cost |

Annual Operating Cost |

Present Worth Cost |

Cost Reduction |

|---|---|---|---|---|

| GAC | $2,140,000 | $304,000 | $6,271,000 | – |

| Resin | $1,090,500 | $99,300 | $3,173,000 | 50% |

Case Studies:

Providing Safe Drinking Water to a Rural Community Impacted by PFAS

PFAS was detected in samples pulled from drinking water in the town of Maysville, NC. ECT2 was contacted by engineering firm, TRC, to provide a solution to treat the contaminated water to safe drinking levels.

Content:

Commercial Airport Uses SORBIX™ PURE from ECT2 to Clean Up Its PFAS

A commercial airport in Scandinavia came to us for help after finding PFAS – including harder-to-treat short chains – in its groundwater.

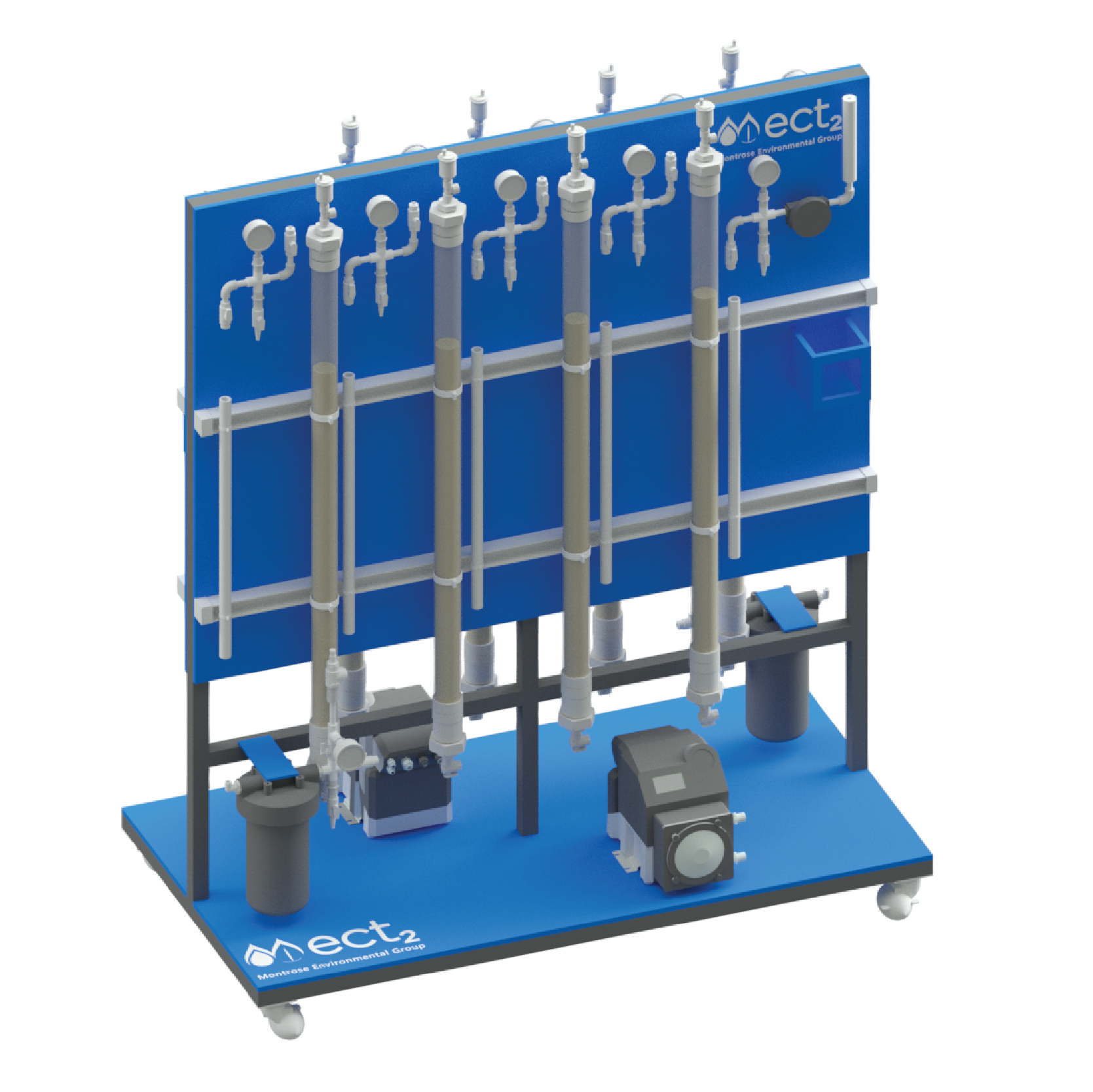

SORBIXTM R SERIES ECT2’s Regenerable System is designed to regenerate the SORBIX RePURE ion exchange resin used in the Series M and Series T product lines. The patented technology provides the lowest overall lifecycle cost and lowest waste on the market.

SORBIXTM R SERIES ECT2’s Regenerable System is designed to regenerate the SORBIX RePURE ion exchange resin used in the Series M and Series T product lines. The patented technology provides the lowest overall lifecycle cost and lowest waste on the market.