Abatement Industrial VOC Abatement

ECT2 has developed advanced technology for the clean, safe, efficient and cost effective abatement of vapor phase volatile organic compounds (VOCs), one of the primary elements of air pollution generated by the Chemical Process Industries (CPI), including chemical plants, refineries, and factories that use toxic chemicals in the course of their production processes. The traditional methods of VOC abatement are thermal oxidation or adsorption via Granular Activated Carbon (GAC). ECT2’s has developed a patent-protected adsorption technology that allows for more efficient, compact systems that can run longer than the competition.

Polymeric Synthetic

Resin Technology

Our lightweight vapor phase VOC abatement solutions incorporate our patent-protected polymeric synthetic resin technology and feature a modular design, small footprint, and ease of installation and access. These systems offer continuous operation to accommodate processing requirements, and media capacity is renewable in place by regeneration, supporting sustainability programs with options for product recovery, energy generation or both.

- Predictable, repeatable performance can be leveraged to streamline compliance management programs and reduce compliance effort over time.

- Low first cost and very low operating cost provide rapid investment return and reduced lifecycle cost.

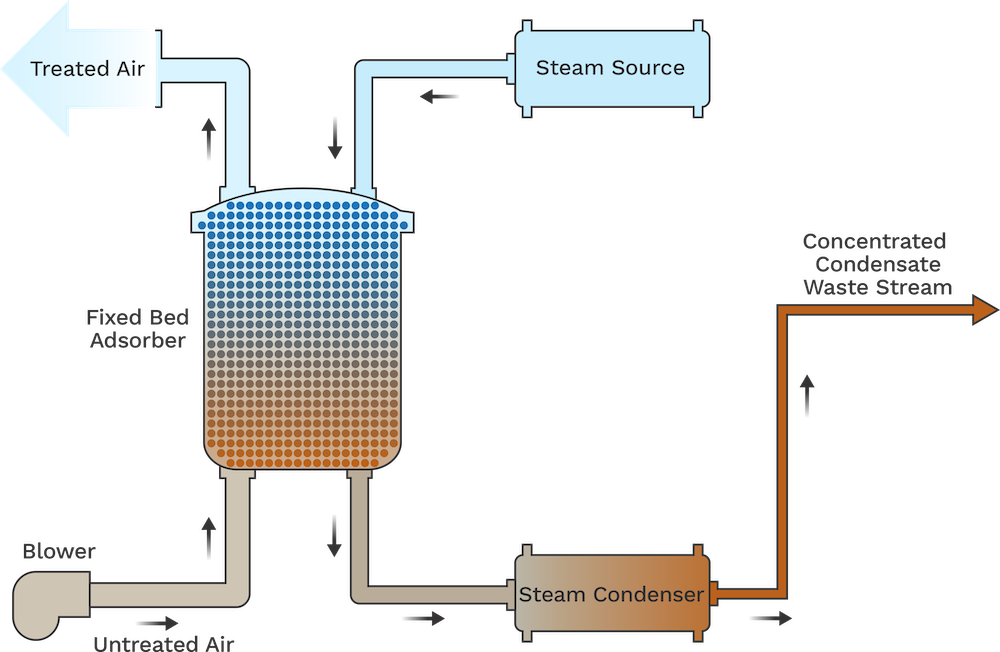

Fixed Bed

Systems

ECT2’s fixed bed systems are compact, lightweight, easily installed, self-contained vapor treatment systems for continuous or intermittent treatment of process vents or other lower-flow environmental applications with high-concentration influent conditions. They use a polymeric medium that selectively removes organics and has a high loading capacity, going years, rather than weeks or months, between media changes out. These systems overcome concerns with GAC, such as:

- O&M cost,

- Compliance

- Process disruption,

- Legacy liabilities, and

- Sustainability.

Additionally, these adsorptive systems are inherently safer than thermal oxidizers and remove the need for potential secondary treatment.

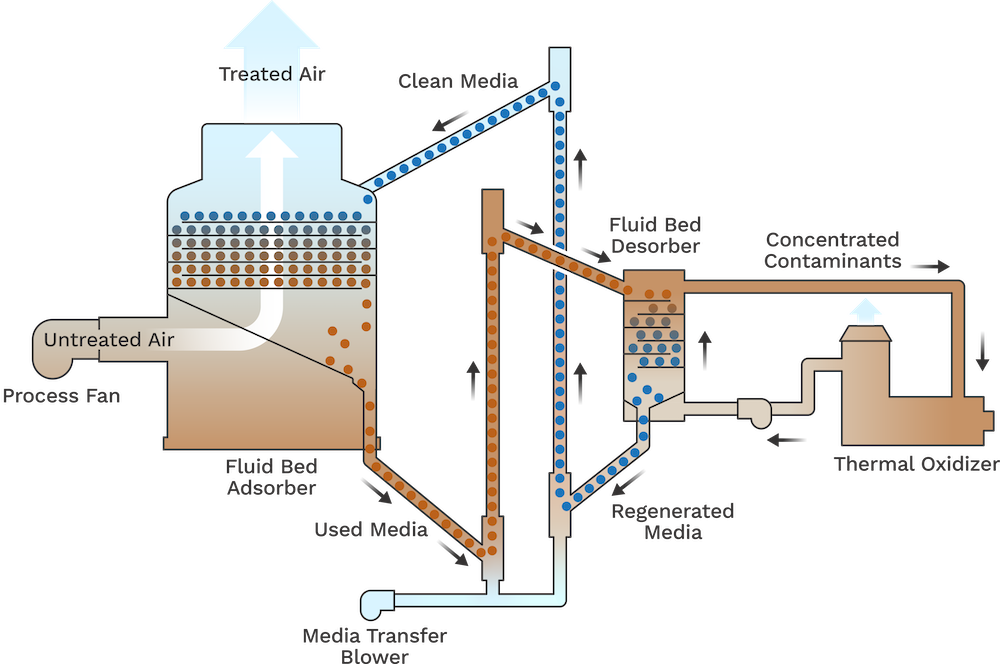

Continuous Moving

Bed Systems

ECT2’s high-flow solutions are designed to operate under continuous service conditions for the removal, destruction, or recovery of contaminants such as organics, aromatics and fragrances from facility air discharges, where extensive removal and energy efficiency are a must. These continuous moving bed (CMB) air treatment systems can be configured to handle flows of 100,000 SCFM or more, with a neutral energy footprint. The systems typically include a fluid bed adsorber to continuously capture the VOCs from plant emissions, a fluid bed desorber to simultaneously renew the media capacity, and a small thermal oxidizer to destroy the organic vapors captured during treatment. Inherently simple, highly reliable, and requiring very little routine maintenance and associated cost, these systems are an integral part of an overall effort to improve reliability, reduce compliance costs, and improve margins.

Alternative to

RTO Units

ECT2’s CMB systems represent a new approach to VOC abatement, offering an alternative to Regenerative Thermal Oxidizer (RTO) units. Complexity and fuel and electricity requirements not only make RTO units unreliable and costly to operate but also result in them generating CO2 emissions of their own. ECT2’s CMB systems concentrate captured VOCs by up to 90 fold, resulting in concentrations that are sufficient to sustain oxidizer operations without supplemental fuel. This combination of oxidizer optimization and elimination of the requirement for supplemental fuel reduces CO2 emissions related to air compliance to nearly zero and reduces energy cost to a fraction of what was previously required.

Case Studies:

Providing Safe Drinking Water to a Rural Community Impacted by PFAS

PFAS was detected in samples pulled from drinking water in the town of Maysville, NC. ECT2 was contacted by engineering firm, TRC, to provide a solution to treat the contaminated water to safe drinking levels.

Content:

Commercial Airport Uses SORBIX™ PURE from ECT2 to Clean Up Its PFAS

A commercial airport in Scandinavia came to us for help after finding PFAS – including harder-to-treat short chains – in its groundwater.