What is regenerable ion exchange?

A helpful Q&A for Flemish businesses with PFAS in their wastewater

Are you researching options for treating PFAS? The Flemish “best available technologies” report* talks a lot about ion exchange with regeneration. This low-cost, increasingly popular approach to treating PFAS has been running successfully for years in other countries but is completely new in Belgium, so we have put together this Q&A to bring you up to speed…

What are PFAS?

Per- and polyfluoroalkyl substances (PFAS) are synthetic compounds found in many industrial and commercial products. They don’t break down in nature and they have been linked with serious health risks, so the Government of Flanders is now imposing limits on how much PFAS you can legally have in your water. Flemish businesses with PFAS in their wastewater are now looking for ways to comply.

What do businesses in Flanders need to do about PFAS?

In Flanders, the limit for any individual PFAS is 20 ng/l. If you are releasing water into the environment and the concentration of any single kind of PFAS in that water is higher than that, then you will need to find a way to remove the PFAS from the water so that the concentration is below this threshold.

In Flanders, the limit for any individual PFAS is 20 ng/l.

How can Flemish businesses remove PFAS from their water?

There are several ways to do this, which are outlined in the study. conducted for the Flemish Region in Belgium by the Flemish Knowledge Center for Best Available Techniques (VITO). Organizations with PFAS contamination in Flanders are required to use one of the technologies mentioned in this report (ie, they can’t use anything that hasn’t yet been tested).

Which of these methods will most of these businesses use?

The best-known method so far is granular activated carbon (GAC). However, we think another technology mentioned in the report – ion exchange with regeneration – will end up being the most popular method in Flanders once more local businesses have noticed its operating costs are much lower than for GAC and other methods.

What is “ion exchange with regeneration”?

The “ion exchange” method begins with soaking special plastic beads called “resin” in salt water, so that chloride ions attach themselves to the positively charged nitrogen ions in the resin. Then, when you add your PFAS-contaminated water, the PFAS ions displace these chloride ions. The result is that your PFAS is attached to the resin instead of floating in the surrounding water. The technology attracts and traps all these molecules so the system can let clean water flow through.

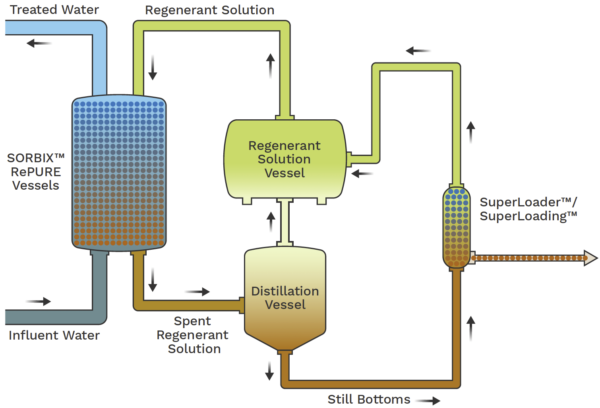

“Regenerating” ion exchange resin is an additional patented step where you use a solution of salt and solvent to remove the PFAS from the resin. Doing this allows you to use the same resin all over again many times, so you don’t have to keep buying new resin and destroying it after every single use. There is only one regenerable ion exchange system available on the market. It is called SORBIX™ RePURE, and you can read more about it here.

Ion exchange with regeneration

The report says that regeneration is not widely practiced. Is this true?

In Belgium this is true. In other countries, however, our SORBIX™ RePURE systems for regeneration have been up and running for several years and are treating PFAS on an unprecedented scale. As the report points out, “in the United States and Australia there are concrete cases where ion exchange with regeneration is carried out on a large scale with processed flow rates between 11.5 m³/h to 415 m³/h”.

One of our customers, a Fortune 500 manufacturing company in the USA, is using SORBIX™ RePURE to treat huge volumes of PFAS at its site. It is the largest industrial wastewater system in the world.

Other customers using this technology include RAAF Base Williamtown Moors Drain in Australia and the United States Air Force Civil Engineering Center in the USA. Collectively we have used this technology to remove PFAS from hundreds of millions of litres of these customers’ water.

Is ion exchange the best method for remediating my PFAS?

It depends. Different problems need different solutions, or combinations of solutions, and no two PFAS contamination sites have exactly the same problem. We have developed our PFAS Tech Select Tool to help you understand your options, but the best way to figure out what will work best is to book a pilot test. That will give you reliable data about your own water to help you make the right decision.

Using regenerable ion exchange to treat PFAS for an industrial customer

What are the advantages of using ion exchange for removing PFAS?

The Flanders report lists the following advantages:

- Efficient PFAS removal with higher capacity compared to granular activated carbon (GAC)

- More efficient removal of short-chain PFAS compared to GAC

- High volume reduction of waste flow possible (300,000:1 – 1,000,000:1)

- Shorter contact times and lower material consumption possible compared to GAC.

- Lower operating costs in the longer term despite the higher material costs per kg of material

This is a good summary. We would add that if you are regenerating and reusing your resin, then the operating costs of ion exchange are even lower – much, much lower. It can cost millions to buy, replace, and incinerate the huge volumes of carbon or ion exchange resin needed to filter out PFAS. What makes regeneration so cost-effective in the long run is that it removes these costs altogether.

What about the disadvantages? The Flanders report says that the operating costs for ion exchange may be lower, but that the initial installation costs may be higher. Is this true?

It is true that the initial installation costs are sometimes higher, but in most cases PFAS takes several decades to remediate. It pays to consider the full lifecycle cost of removing that PFAS, rather than just looking at the cost of the initial installation.

The report says that regeneration requires large amounts of solvents and/or brine. Is this true?

This depends on whether you can reuse the solvents and brine. The report also mentions that the associated costs can be reduced if they are recovered after regeneration. This is exactly how our process works: after using our solvent and brine to remove the PFAS from the resin, we distil it so that, like the resin, it can also be reused. This results in less cost and less waste.

The report says that ion exchange is more sensitive to blockages due to the presence of suspended solids and some dissolved solids in the matrix. Is this a problem?

Ion exchange resin is affected by suspended and dissolved solids. This is why robust pre-treatment is needed. ECT2 has industry-leading expertise in designing pre-treatment systems that allow us to get the most out of the ion exchange treatment step that follows. We have dozens of full-scale ion exchange projects around the world that attest to the effectiveness of this approach.

The report says PFAS-containing waste is formed when using ion exchange resin, and that it must be removed and processed. Is this true?

This is true of all treatment technologies, but using ion exchange resin means that the problem is much smaller in scale. As the report points out, ion exchange resin is more efficient than GAC in removing PFAS, which means you need much less of it to remove the same volume of PFAS. The combination of adsorption and ion exchange produces a PFAS removal capacity that is 13x more effective in comparison to other technologies.

For businesses that regenerate and reuse their resin, there is even better news: you end up with virtually no PFAS-containing waste at all. Following regeneration, the PFAS-laden regenerant solution is processed through our distillation and SuperLoading™ process, reducing waste generation by orders of magnitude. You can achieve up to 99% less waste generation with this method. Since the cost of waste disposal is a function of volume, the cost of the disposal is negligible in the context of the full system.

The report says there is uncertainty about the completeness of degradation and associated air emissions from the combustion of single-use resins or concentrate streams from regeneration. Is this true?

When it comes to incineration, this is true of any method for separating and/or concentrating PFAS. The difference is that the amount of waste generated with SORBIX™ RePURE is orders of magnitude below any other commercialized treatment technology.

Our distillation and SuperLoading™ process

reduces waste generation by orders of magnitude

The report says that based on supplier information, it is recommended to use ion exchange resins with GAC as a pre-treatment step to remove already dissolved organic substances up to < 1 mg/l. Is this good advice?

At ECT2 we tailor our pre-treatment to the project requirements. This often involves GAC because it is very effective at removing dissolved organic substances. Other pre-treatment technologies we commonly use include multimedia filtration, flocculation, ultra-filtration, and sand filters.

What do I get out of pilot testing?

Pilot testing allows ECT2 to accurately dimension the full-scale solution. This means fewer assumptions need to be taken, which in turn reduces the cost. The key question that is answered by a pilot relates to the operational cost. How frequently will regeneration be needed to ensure that the PFAS in the effluent meets the regulatory requirements? This cannot be accurately judged based on water chemistry alone.

Put it to the test

Every PFAS challenge is different, but regeneration has clear advantages for many businesses in Flanders. If you would like to explore your own options, to test different technologies on your own water, or just to learn more, then please feel free to call Stefan Tassens at +32 478 767 067 or use the contact form below.

* The study, titled ‘Best available techniques (BAT) for the treatment of PFAS-containing industrial wastewater and drainage water’, was conducted for the Flemish Region in Belgium by the Flemish Knowledge Center for Best Available Techniques (VITO).