Opportunity

The Air Force Civil Engineering Center (AFCEC) funded a field study coupling ECT2’s SORBIX™ RePURE Regenerable Ion Exchange Resin (IX) System with Electrochemical Oxidation (EO). This study aimed to prove the ability to capture PFAS compounds on IX, regenerate the IX using a solvent based solution and produce a concentrated PFAS liquid stream. The concentrated liquid would then be distilled to recover the solvent and produce still bottoms, highly concentrated in PFAS, that would then be subjected to EO to destroy the PFAS compounds. This study would represent a first-of-its-kind field demonstration.

Challenge

ECT2 was subcontracted to design, build, install, commission and optimize, and train field staff to operate a 3-5 gpm forward flow regenerable treatment unit coupled with regeneration and distillation equipment. The end objective was to generate 40-50 gallons of concentrated PFAS still bottoms from contaminated groundwater at two different locations located on Wright-Patterson Air Force Base near Dayton, Ohio.

Solution

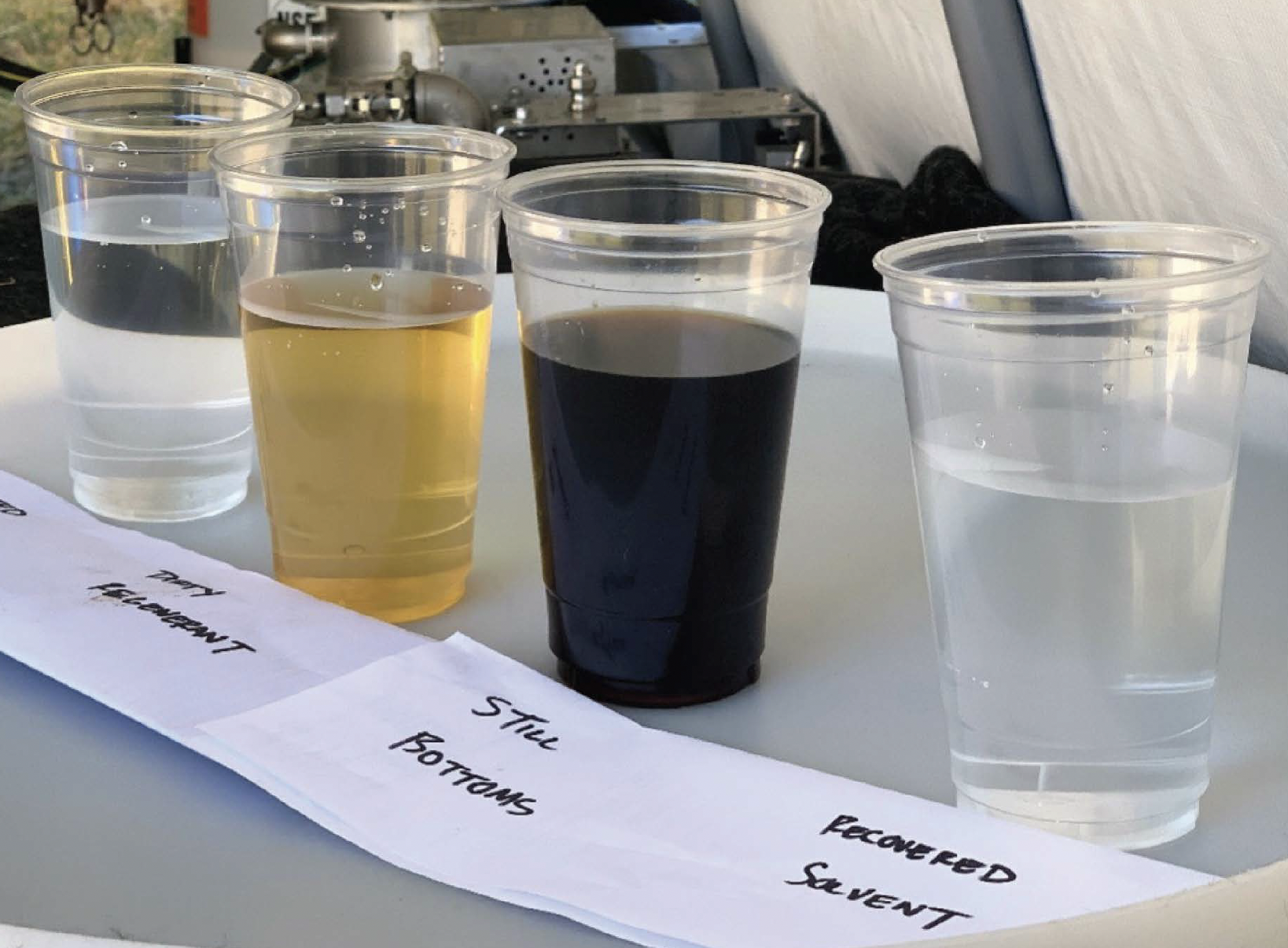

ECT2’s SORBIX RePURE regenerable resin pilot system (RPS-1) was developed using ECT2’s SORBIX RePURE ion exchange resin, fabricated inside a Conex shipping container, mobilized to the base and set up to treat the specified water. The SORBIX RePURE system removed PFAS from site groundwater and when the lead treatment vessel approached a predetermined loading, the vessel was taken offline and the resin restored with the accompanying regeneration system situated alongside the RPS-1 system. Due to the regeneration and distillation process involving a flammable solvent/brine mix, particular design considerations for safety had to be taken into account. At the conclusion of each regeneration event, distillation was conducted to further concentrate the PFAS removed from the resin during regenerations. The distillation process recovered the solvent for reuse and produced a highly concentrated PFAS/brine solution.

ECT2 partnered with AECOM for this pilot study, which was the first-ever field demonstration of ECT2’s regeneration technology coupled with AECOM’s DE-FLUORO™ on-site PFAS destruction technology. The still bottoms produced from the distillation process underwent electrochemical oxidation which resulted in destruction of the concentrated PFAS. This proprietary technology was the result of a partnership between AECOM and the University of Georgia. The overall treatment process has achieved non-detect levels of PFOS and PFOA in the treated groundwater discharge, while the removed PFAS are concentrated into still bottoms and destroyed onsite. As a result, this study showed that the system effectively removed PFAS from the contaminated water and that the resin was successfully regenerated, demonstrating ECT2’s ability to quickly design and execute effective pilot studies onsite at clients’ facilities. This pilot system has treated more than 500,000 gallons of PFAS-impacted groundwater at two sites at Wright-Patterson Air Force Base.