Opportunity

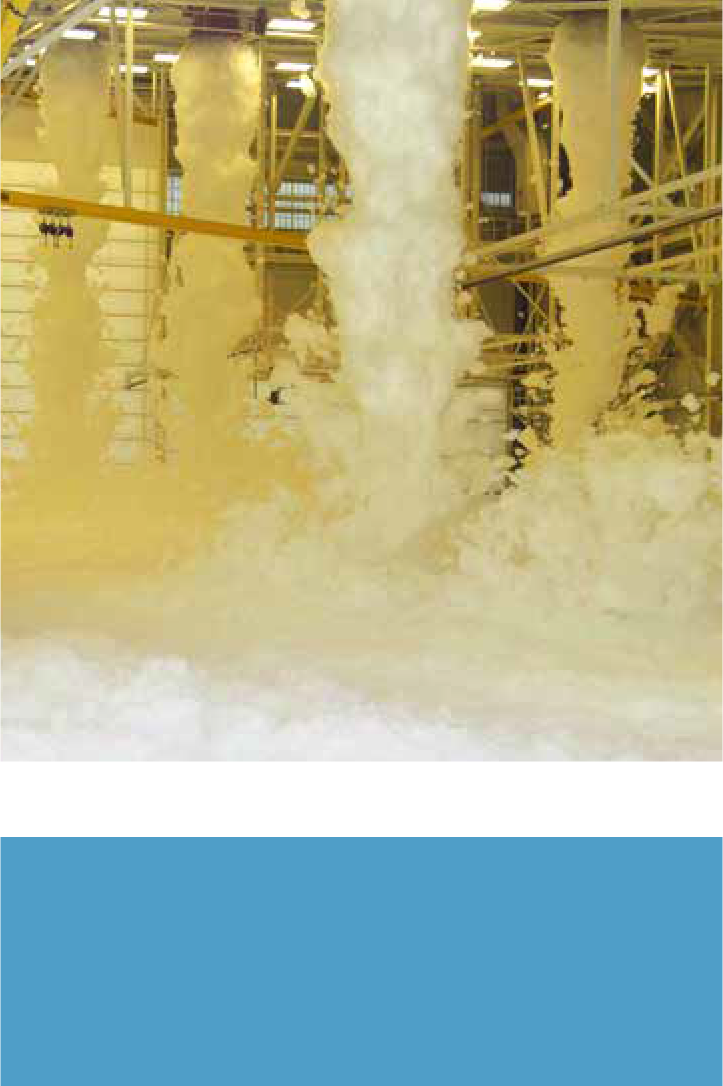

At the current time, industry regulations are in the process of changing to require all fire suppression systems using 6 and 8 carbon chain PFAS compounds to change to safer alternative foams. This changeover period is certain to produce a large quantity of PFAS impacted water that will need treatment – which ECT2 is uniquely positioned to treat onsite as an alternative to costly offsite disposal options. In 2020, ECT2 was engaged by a global aviation services company for one of their airport locations in the Northeastern United States. Due to ECT2’s experience treating contaminated water at airports, the customer requested the team to assess the situation, develop a plan and remediate an AFFF release in an aircraft hangar. The end goal was to treat the PFAS contaminated water to meet Northeast drinking water standards and discharge it onsite.

Challenge

Following the AFFF discharge, most of the foam was collected in underground storage tanks. While AFFF releases are a relatively common occurrence in the US, the solution and environmental impact to remediate such as release can be expensive. AFFF waste is notoriously difficult to treat, filled with pre-cursors and other hard to treat compounds – and as a highly concentrated stream, it is difficult to treat with conventional media techniques. With 160,000 gallons of highly concentrated PFAS water to treat and discharge onsite, ECT2 was up to the challenge ECT2 was provided with initial information about the discharge, including the PFAS concentration in the water. After conducting a more extensive analysis, the actual water chemistry was 1000 times more concentrated than initially reported. ECT2 had deployed the system ready to treat water to the ppb level to find out that it was actually at a ppm level.

Solution

The waste profile was less than 4% of initial projections – culminating in >50% overall cost savings to the customer and a reduced offsite waste footprint, while producing water onsite that can be safely discharged. The development of this technology, called SORBIX™ AvPURE, has since been deployed at sites across the US, providing customers with a safe onsite treatment alternative to costly offsite disposal.