BACKGROUND INFORMATION

As an essential tool for firefighting agencies and emergency services worldwide, Aqueous Film Forming Foams (AFFF) have been favored to provide a rapid and effective solution to suppress fires. Unfortunately, AFFF contains per- and polyfluoroalkyl substances (PFAS) which have both adverse environmental impact and potential health risks. PFAS are known as a ‘forever chemicals’, due to their persistent nature and accumulation in the environment, including water sources as well as in the bodies of humans and wildlife. Due to growing concerns, there is a global shift towards fluorine-free firefighting foam, and many manufacturers and firefighting agencies are in the process of researching and transitioning to alternatives.

However, the shift towards these fluorine-free foams, such as synthetic fluorine-free foams (SFFFs), isn’t an easy task. It requires a re-evaluation of strategies, equipment, and training. Additionally, the changeout process isn’t as simple as it sounds, due to inherent difficulties from a cleaning perspective, such as leftover foam sorbed or partitioned into an asset.

RESEARCH & DEVELOPMENT

ECT2, a company committed to treatment technologies for emerging compounds, has been removing PFAS from the environment with water treatment for over seven years. In that time, they’ve treated over 7 billion gallons of PFAS impacted water. With the timeline to transition away from AFFF becoming clear in 2021, ECT2 started researching a solution for AFFF cleanout and transition services. With a dedicated in-house R&D lab, the team started asking questions such as:

- Treatment Objective: How clean is clean?

- Waste Generated: How will generated waste be handled? How can it be minimized?

- Avoiding Rebound: How to avoid the PFAS permeated material from reintroducing PFAS into a fluorine-free foam?

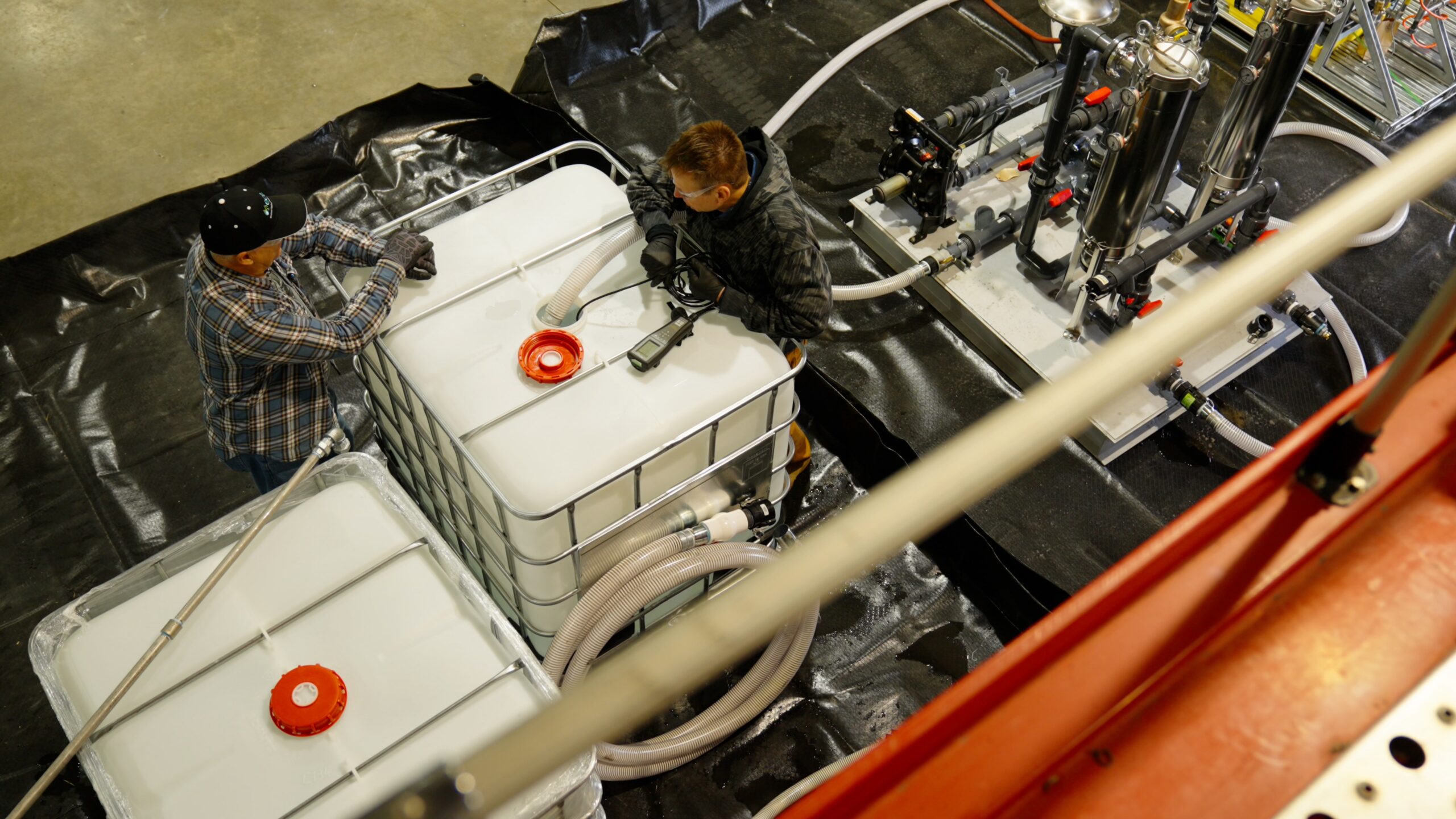

To address these questions, ECT2 set up a series of experiments with different cleaning solutions and conditions. In total, more than 21 different solutions and configurations were experimented with. From there, the better-performing solutions were then down-selected for additional tests, which involved the introduction of various contact times, temperatures, and shear velocity. The mass of PFAS between the different cleaning processes was evaluated while the amount of rebound was observed. Ultimately, ECT2 has arrived at a two-part cleaning solution that performs considerably better than triple rinse solutions. ECT2’s solution uses water, results in less rebound, and generates less waste to minimize disposal costs. Additionally, the two-part cleaning solution can accomplish the cleaning in shorter time, which allows fire-protection services to be restored sooner.

OUR EXPERIENCE

ECT2’s team has worked for years with airports, aircraft rescue and firefighting groups, the Department of Defense, industrial manufacturers, and associated industries to remediate their PFAS-impacted water challenges. Through that, we bring our experience and knowledge to rinse, clean, and transition AFFF fire suppression systems to fluorine-free foam.

ECT2’s team has worked for years with airports, aircraft rescue and firefighting groups, the Department of Defense, industrial manufacturers, and associated industries to remediate their PFAS-impacted water challenges. Through that, we bring our experience and knowledge to rinse, clean, and transition AFFF fire suppression systems to fluorine-free foam.

On complicated projects like this, it’s vital to partner with a technical field services team that brings extensive experience in AFFF changeout projects. ECT2’s team brings an established track record with proven turnkey technology and techniques. To our clients, we are able to offer:

- Efficient draining and containerizing AFFF concentrate

- Effective decontaminating and flushing of AFFF-containing tanks, hydrants, and piping networks

- Capturing and containerizing the rinsate generated during the process, with an emphasis on minimizing waste generated

- Treatment of rinsate to avoid high disposal costs with safe discharge

- Demonstrated experience in the management, transportation, and disposal of any liquid or solid waste generated during the process

- Refill with new synthetic fluorine free foam and allow for any needed repairs or fire protection upgrades to be accomplished.

- Comprehensive execution and documentation of the process from start to finish including appropriate environmental, safety and occupational health concerns are met.

CONCLUSION

While the transition from PFAS firefighting foams to fluorine-free alternatives is a significant undertaking, partnering with an experienced team can streamline the approach. ECT2’s team understands the overall objectives and potential complications, offers a demonstrated know-how, has differentiated technology, and comprehensive service offerings.

Start the conversation today with our team by filling out this form, and one of our experienced team members will be in touch with you soon!

David Kempisty, Ph.D., P.E.

David Kempisty, Ph.D., P.E.